Crest Ultrasonic

Crest Ultrasonics Group is a leader in the ultrasonic cleaning and ultrasonic welding and joining industries, with facilities in North America, Europe, and Asia and customers in a hundred countries around the world.

Crest Ultrasonics

Crest Ultrasonics keeps customer satisfaction in mind. As the largest privately-owned company in the ultrasonic industry, Crest Ultrasonics works to produce top-quality welding products for customers in the welding industry around the world.

Products

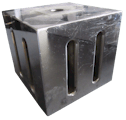

Crest Ultrasonics produces a number of products that can aid in any welding project. Rochester Industrial Services, Inc. is proud to service its products, including:

Issues With Crest Ultrasonics Products

Problems can arise with any product. Problems common to Crest products include error codes that may occur while operating Crest products, such as:

- Amplitude-LED

- Temperature-LED

- Error-LED

- Low level-LED

- Operation Light Failing

- Application does not clean properly

- Generator does not operate at full power

- Loud, screaming noise during operation (not a code)

Resolutions

The above problems can become major issues if not properly treated. Fortunately, Rochester Industrial Services can help with solutions to prevent the problems from growing worse:

- Amplitude-LED – Immerse transducer completely (liquid must be completely covering transducer).

- Temperature-LED – Reduce environment temperature, clean air inlet, or repair by manufacturer.

- Error-LED – Connect matched transducer, change conditions, degas cleaning liquid, immerse transducer, check connections or wiring, change transducer (or repair it at manufacturer), repair at factory, or check power supply.

- Low level-LED – Check liquid level.

- Operation light failing – Check power supply, check pre-fuse, or immerse transducer.

- Application does not clean properly – Degas cleaning liquid or reduce cleaning.

- Generator does not operate at full power – Immerse transducer.

- Loud, screaming noise during operation (not a code) – Reduce output, change liquid temp, change solvent concentration, quietise tank walls, or reinforce sidewalls of tank.

Conclusion

If problems persist or the solutions do not resolve the issues, contact Rochester Industrial Services, Inc. for service and assistance.